Transferring Knowledge to AUD Engineering Students

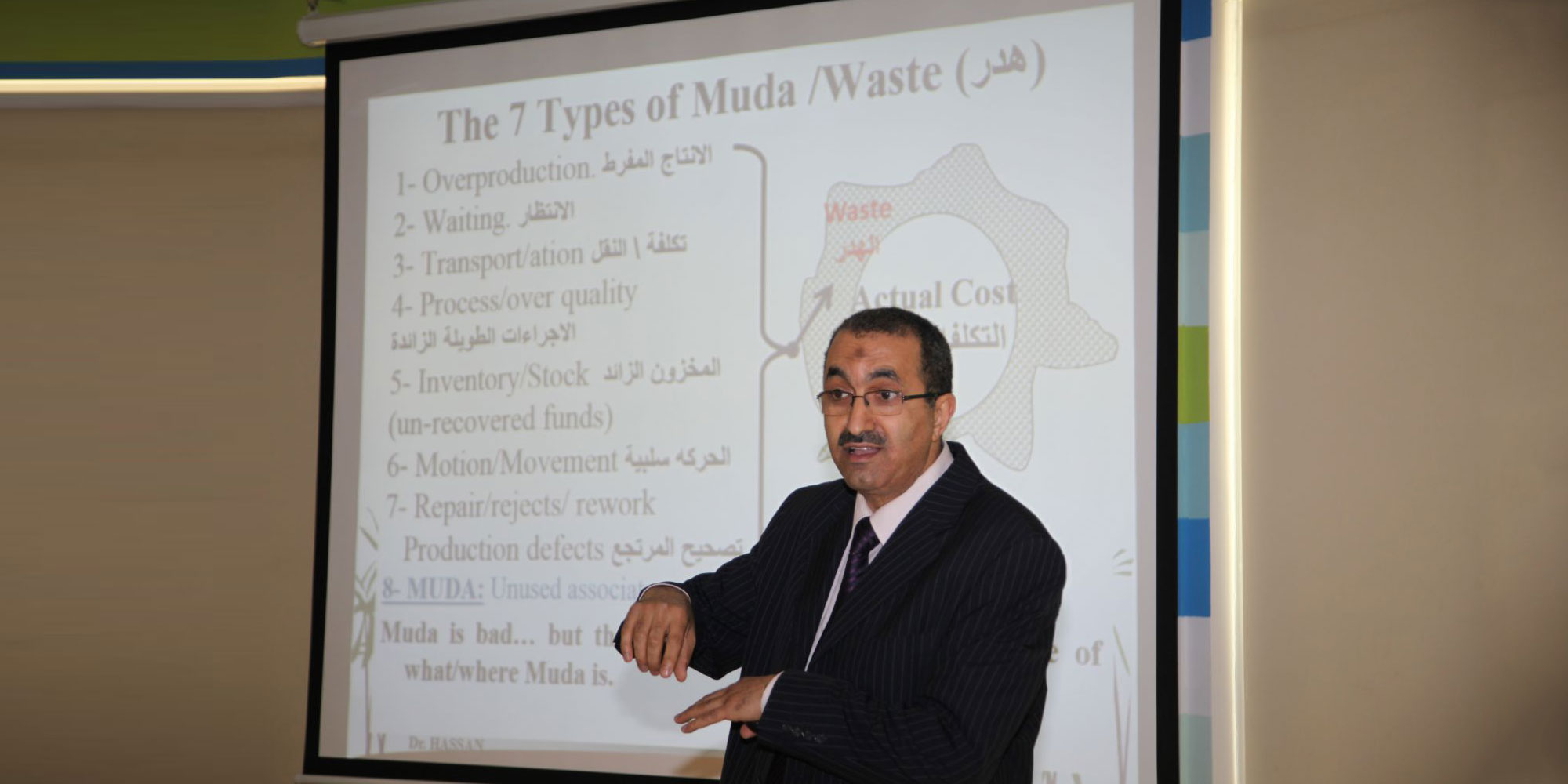

The American Society of Mechanical Engineers (ASME) – AUD Student Branch recently hosted Dr. Hassan Abulmouti, a Professor of Mechanical Engineering and previously with Toyota, to share the details behind Kaizen, the Japanese philosophy that lead to Toyota’s success.

Kaizen has been adopted to define the Toyota Way; its activities aim at improving all functions of the business, even by small steps, and through involving all employees.

"Kaizen is the Japanese word for "improvement" or "change for the best”. It refers to the philosophy and practices that focus on continuous improvement of processes in manufacturing, engineering, and business management. The value of the talk was in giving AUD’s Engineering students an idea of the philosophies used by large, successful engineering companies, giving them the chance to apply it to their own lives,” commented Dana Fawaz, ASME AUD President.

About Kaizen Philosophy

Kaizen (改善) is the Japanese word for "improvement" or "change for the best”. It refers to the philosophy or practices that focus upon continuous improvement of processes in manufacturing, engineering, and business management. However, Kaizen continued to improve the processes for many types of businesses including the healthcare sector. Kaizen is used worldwide and it became the central pillar for processes improvement in many big companies such as Toyota, where it has been adopted to define the TOYOTA WAY (Toyota’s DNA). In a simple definition, one can say that Kaizen activities aim at improving all functions of the business, even by small steps, and through involving all employees. It is a collective effort that makes the process more efficient, effective, under control, and adaptable. The improvements are usually accomplished at little or no expense and without sophisticated techniques or expensive equipment. Applying Kaizen on complex processes starts by breaking them down into their basic elements or sub-processes and then improving them. Kaizen Division in such companies has role by educating employees on with how to produce efficiently with limited resources (man, material, and machine), make continuous improvements for the organization, cost reduction and cost optimization in order to save manpower, space, equipment, material, etc, continues training and education for the employee of the organization and involve them in Kaizen activities and increase the productivity of the employee in the organization. [1]